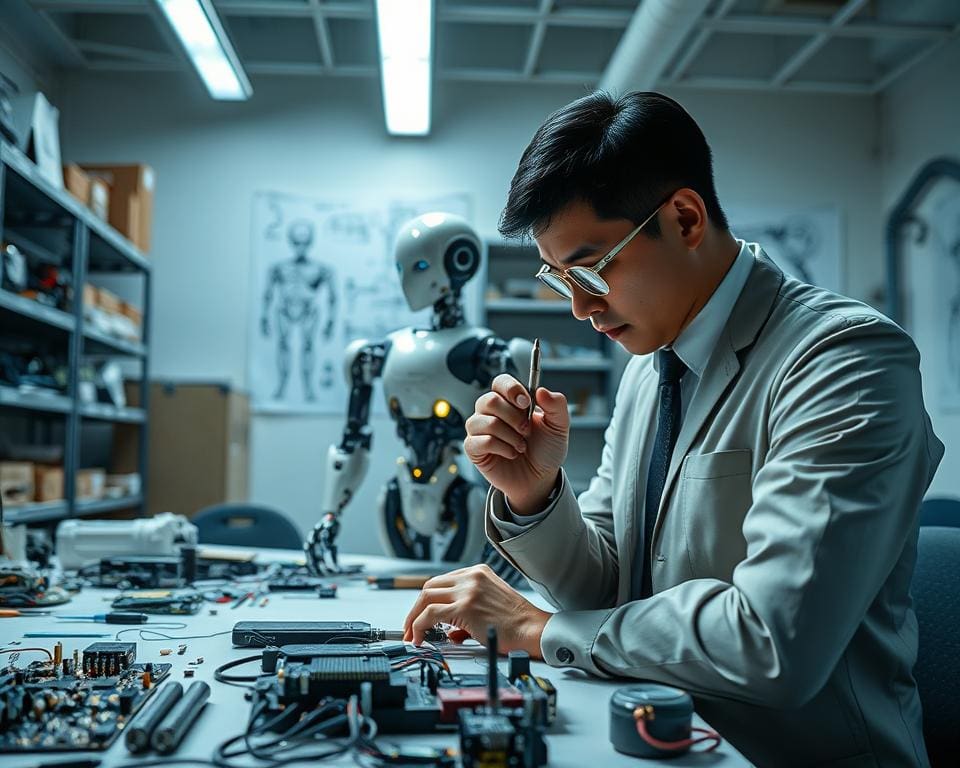

The robotics technician role is built around keeping machines working with precision. Technicians diagnose faults, carry out repairs and perform routine robot maintenance across industrial, service and collaborative applications. Their work ensures uptime, safety and consistent output for factories, hospitals and logistics hubs in the United Kingdom.

Repairs span clear domains: mechanical systems such as actuators, gears and end-effectors; electronic and control systems including power supplies, drives and PCBs; and software, firmware and network issues that demand timely updates and secure connections. Preventative routines—inspections, lubrication and spare parts management—round out the skill set needed for effective automated systems repair.

Robotics repair UK teams support major sectors from automotive and food processing to pharmaceuticals and research. Skilled technicians reduce downtime and extend equipment life, making a tangible contribution to the economy. This article serves as a practical, evaluative guide for facility managers, engineering leads and aspiring technicians on what to prioritise when choosing tools, spares and service practices.

What does a robotics technician repair?

Robotics technicians fix a broad range of faults across industrial and service platforms. Their work blends hands-on mechanical skill with controller diagnostics and safety checks. Tasks vary from urgent field fixes on a factory line to careful service robot troubleshooting in public spaces.

Common repair scenarios in manufacturing

In manufacturing settings the most frequent issues include worn gearboxes, encoder failures and motor overheating. High-cycle operations often damage end-of-arm tooling and teach-pendant faults can halt production.

Typical remedial actions include bearing and seal replacement, encoder recalibration and drive diagnostics. Technicians reconfigure PLCs and robot controllers to restore safe, repeatable motion.

UK workshops meet systems from FANUC, ABB, KUKA, Yaskawa (Motoman) and Universal Robots. Each brand has proprietary components and different support channels that shape the approach to manufacturing robot repairs.

Repairs in service and collaborative robots

Service robots and cobots demand gentle handling of delicate sensors, soft-grip end-effectors and embedded control boards. Torque-limited actuators can suffer misalignment from repeated human interaction.

Safety is central during collaborative robot maintenance. Technicians isolate power, run functional safety checks under ISO 13849 and validate collaborative modes after any intervention.

Repair priorities change by environment. Logistics cobots need durable batteries and wheels, healthcare assistants require hygiene-compatible seals and hospitality robots focus on lightweight, user-safe grippers.

Case study snapshot

A UK factory reported a pick-and-place cell losing positional accuracy. Diagnostic readouts showed encoder degradation on a Yaskawa unit. The team logged the fault, removed the coupling and fitted a new encoder.

After recalibration the robot regained cycle accuracy and downtime dropped. The episode highlighted value in spare encoder stock and routine checks to speed future manufacturing robot repairs.

Organisations weigh in-house repair against OEM contracts. In-house teams offer rapid response and lower ongoing cost. OEM service gives deeper warranty coverage and branded support for complex industrial robot faults.

Mechanical systems and structural repairs for robots

Robots rely on solid mechanical systems to keep production moving and to protect staff. Skilled technicians focus on robust inspections and service plans that reduce downtime and extend machine life. This section outlines practical steps for actuator issues, end-effector faults and structural servicing that matter on UK shopfloors.

Actuators, gears and transmission maintenance

Electric servomotors dominate industrial lines in the UK, yet stepper motors, pneumatic units and hydraulics still appear in specialised cells. Early signs of failure include vibration, increased current draw, loss of torque and odd noises.

Diagnostics start with clamp meters, vibration analysers and thermal imaging to spot hotspots and imbalance. Motor drive tests, gearbox inspections and backlash measurement follow. Technicians check couplings and alignment, then decide between refurbishing a unit and full replacement based on compatibility with controller drives.

Transmission servicing includes gearbox lubrication, torque specification checks and scheduled interval work set by the manufacturer. Correct grease type and application frequency prevent premature wear and protect gears and shafts.

End-effectors and gripper repairs

End-effectors vary from parallel and angular grippers to vacuum cups and magnetic tooling. Each has distinct wear points and simple fixes can restore performance quickly.

Common faults include worn finger pads, leaking pneumatic seals and faulty vacuum pumps. For gripper repair, replace seals, test pneumatic lines and choose suction cups matched to the part surface. Sensor misalignment may require re-teaching gripping positions and adjusting thresholds.

Calibration and payload validation are essential after work. Re-teach positions, validate force and torque sensors and trial picks at several speeds to confirm reliability. Assess third-party tooling against OEM units for fit, warranty and long-term cost.

Frame, joints and bearing servicing

Structural checks begin with visual inspections for cracks and corrosion, important in food plants and coastal sites. Fastener torque checks and joint play assessments reveal hidden problems before they become critical.

Bearing failure stems from fatigue, contamination or lubrication breakdown. Extraction and inspection let technicians decide on replacement bearings from trusted suppliers such as SKF or NSK. Using proper parts ensures compatibility and life expectancy.

Alignment and backlash correction use dial indicators or laser tools to restore precision. After repairs, restore guards, covers and safety interlocks, then run the robot in a safe mode to confirm behaviour prior to returning to full production.

Electronic and control system troubleshooting

When electronics falter, a calm, methodical approach saves downtime and preserves safety. Start by isolating the fault and confirming safe working conditions. Use manufacturer diagnostic tools such as ABB RobotStudio or KUKA KRC diagnostics where available. Record alarm codes and status LEDs before power cycling to keep a traceable trail for later analysis.

Power supplies, drives and motor controllers

Begin with mains and DC bus checks, fuses and earth continuity. Inspect for capacitor ageing in power supplies and for drive overheating signs. Use an oscilloscope for ripple analysis and an insulation tester to check isolation. In motor controller troubleshooting, read drive alarm codes, monitor axis communication and review thermal management. Replace capacitors or swap drive modules when repairs are reasonable. Store replaced units safely for warranty or return to the supplier.

Sensor replacement and calibration

Sensors range from incremental encoders to vision cameras and LIDAR. Handle sensitive devices with anti-static precautions and verify connector pin mapping before mechanical alignment. Follow calibration protocols: encoder zeroing, vision system calibration plates and force sensor tare routines. Prefer OEM parts from reputable suppliers such as Sick, Keyence, Omron or Renishaw for critical replacements. Ensure traceable calibration when accuracy is essential.

PCB and wiring repairs

Wiring faults industrial robots often appear as intermittent signals, abrasion or connector corrosion. Use continuity checks, wiggle tests and thermal imaging to find hotspots. For PCB repair robot teams should look for burnt parts, cold joints and solder bridges. Replace common components like diodes or regulators when safe to do so. Send complex boards to certified repair centres when required.

Good connector and harness management reduces repeat faults. Check crimp quality, use bootlace ferrules and IP-rated connectors with proper strain relief. Keep wiring diagrams and version-controlled schematics current. Maintain spares for critical harness assemblies to speed repairs and ensure compatibility during robot electronics repair.

Software, firmware and network maintenance

Keeping robot systems reliable demands a clear plan for software, firmware and network care. Technicians must treat updates, debugging and networking as linked tasks that protect uptime and safety. The following guidance frames practical steps for workshop teams and plant engineers across the UK.

Firmware updates and rollback strategies

Firmware delivers bug fixes, safety patches and performance gains but can create incompatibilities. Safe practice starts with staging robot firmware updates in a test cell and keeping full backups of controller configurations.

Keep organised archives of previous images and document every firmware version. Use vendor tools such as Universal Robots Polyscope or ABB RobotStudio when available. Have a clear rollback procedure that includes restoring the prior image, validating motion profiles and running safety checks before returning to production.

Control software debugging and reconfiguration

Effective control software debugging relies on systematic log analysis and fault reproduction at low speed or in simulation. Use step-through modes and variable-watch features in the robot environment to pinpoint errors.

After mechanical repairs, re-teach paths, update payload and tool centre point (TCP) settings and adjust speed and acceleration to match repaired components. Ensure PLC and robot networking remains synchronised, then run regression tests with MES interfaces to confirm I/O mapping and error handling.

Industrial networking and cybersecurity checks

Network health checks should verify industrial Ethernet links, switch port statistics and avoid duplex mismatches. Use managed switches and VLAN segmentation to isolate control traffic.

Adopt strong passwords, disable unused services and apply firewalls and VPNs for remote access. Follow NCSC guidance to raise robot cybersecurity UK standards on site. Coordinate OS and control software patch windows with production schedules and keep fall-back plans in case a patch impacts operations.

Remote diagnostics offer fast support from OEMs, but require secure protocols, explicit operator consent and careful logging. Balancing remote assistance with local control helps protect productivity while preserving industrial network security.

Preventative maintenance and inspection routines

A proactive maintenance culture keeps production moving and extends asset life. This section outlines practical routines for daily checks, deeper inspections and supply planning that fit British manufacturing realities.

Daily visual checks should spot leaks, unusual wear and loose fastenings. Weekly checks add electrical and mechanical verification. Monthly inspections dive into alignments, encoder signals and motor current trends. Annual full-service routines tie together all findings and refresh firmware and safety tests.

Condition monitoring robotics relies on vibration analysers, thermal cameras and current signature analysis to spot trends before failures. Integrate these tools with a CMMS to log metrics such as backlash, temperature profiles and cycle counts. Use trend alerts to trigger maintenance and reduce unplanned downtime.

Lubrication, cleaning and environmental considerations

Follow manufacturer guidance on grease or oil type, application amounts and re-lubrication intervals. Use food-grade lubricants in hygiene-sensitive lines and avoid contamination during application. Lubrication robots UK can perform precise dosing in repetitive tasks, cutting contamination risk and ensuring consistent coverage.

Cleaning regimes must remove dust and residues without exposing electronics to pressure wash. Protect sensitive assemblies with IP-rated enclosures and control humidity in coastal or chemical plants to limit corrosion. Apply ESD precautions for electronic work and strict hygiene protocols where robots handle consumables.

Spare parts strategy and inventory management

Identify critical spares such as encoders, controllers and gearbox assemblies. Classify items for just-in-case stocking versus just-in-time replenishment. A spare parts strategy robotics should balance capital in stock with the cost of production stoppage.

Use vendor consignment, authorised distributors or local repair centres to reduce lead times and ensure genuine parts from brands like ABB, FANUC and Universal Robots. Set reorder points and minimum stock levels in the CMMS, review them after incidents and run regular audits to avoid obsolescence.

Skills, tools and certification for robotics technicians

Robotics technician skills combine hands‑on mechanics, electrical know‑how and control‑system literacy. A competent technician needs mechanical aptitude for actuators and bearings, electrical troubleshooting for drives and sensors, and basic programming for robot languages and PLC ladder or structured text. Soft skills matter too: clear documentation, calm decision‑making under downtime pressure and good communication with production and safety teams keep lines moving and risks low.

Robust toolkits and accurate test equipment are essential. Typical robotics tools UK teams carry include torque wrenches, bearing pullers, dial indicators and feeler gauges for mechanical work, plus multimeters, clamp meters, oscilloscopes and soldering stations for electronics. Use of ESD‑safe tool kits, insulation testers and compression tools for pneumatic lines protects components. Diagnostic software such as RobotStudio, KUKA.WorkVisual and manufacturer packages, together with laptop interfaces and secure remote access, speed fault finding.

Formal training and recognised certification underpin career progression. Relevant programmes range from NVQs and HNC/HND in mechatronics or electro‑mechanical engineering to apprenticeships focused on automation. Manufacturer training from ABB, FANUC, KUKA, Universal Robots and Yaskawa offers access to proprietary diagnostics and authorised spare parts, while professional bodies like the Institution of Engineering and Technology support ongoing learning. Short courses in industrial cybersecurity and safety standards (ISO 12100, ISO 10218, ISO 13849) enhance credibility.

For those targeting advancement, blend practical experience with continuous study. A maintenance technician qualification opens entry‑level roles, and further engineer training robotics can lead to positions as a robotics engineer or automation specialist. Lifelong learning, careful use of diagnostics and a disciplined safety mindset ensure technicians remain effective as industrial robotics evolve.