Manufacturers across the United Kingdom are asking a simple, urgent question: How do robots improve industrial efficiency? The shift toward industrial automation is no longer niche. Global adoption has surged in sectors from automotive to food and beverage, driven by suppliers such as ABB, KUKA, FANUC, Universal Robots and Yaskawa.

In practical terms, efficiency means higher throughput, longer uptime, improved yield, shorter cycle times, consistent quality and a lower total cost of ownership. This article will show how manufacturing robotics UK projects deliver those outcomes, and where robotic efficiency aligns with broader automation benefits.

We draw on trusted sources — International Federation of Robotics, Make UK, vendor white papers and peer‑reviewed ROI studies — to give plant managers and procurement teams clear, actionable insight. The following sections move from an overview to robot types, enabling technologies, economics and UK implementation, finishing with a product‑review perspective to help buyers choose systems that produce measurable gains.

How do robots improve industrial efficiency?

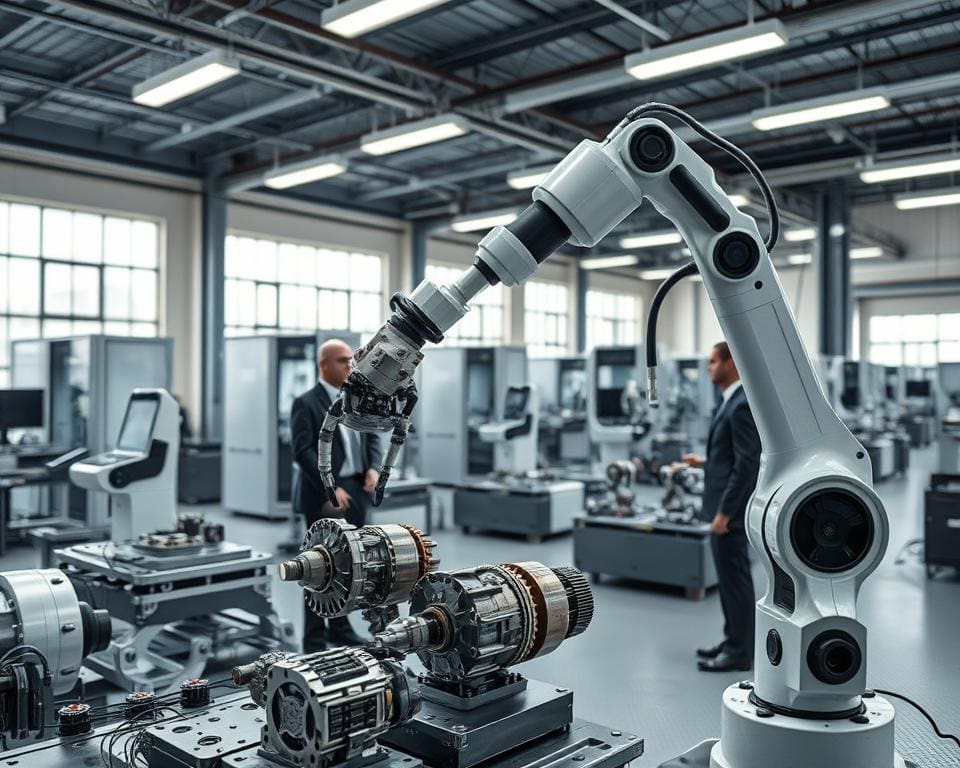

Robots transform factory floors by combining repeatable precision with nonstop operation. They take on hazardous or repetitive work, reduce human risk and keep production moving across shifts. This steady performance underpins many robotics productivity benefits seen in modern plants.

Overview of robotic contributions to productivity

Robotic systems deliver consistent part-to-part quality that is hard to match manually. Vision-guided inspection and programmed motion help lower defect rates and raise first-pass yield.

Automation lets managers scale capacity through faster cycle times and reliable multi-shift operation without fatigue-related quality drops. Preventive maintenance and industrial components improve mean time between failures, supporting longer production runs.

Applying robotics to repetitive tasks frees employees for higher-value work such as process improvement and quality control. Practical guidance on targeting suitable workflows appears in industry write-ups like the one at how to boost productivity with automation.

Key performance indicators improved by robots (throughput, uptime, cycle time)

Throughput improvement is a frequent headline benefit. High-speed delta and SCARA cells can multiply parts-per-hour compared with manual handling, lifting overall line output.

An uptime increase follows from predictable robotic operation and scheduled servicing. Less unplanned stoppage means the line spends more time producing, improving utilisation and delivery reliability.

Cycle time reduction happens when motion planning and task-specific robots trim seconds from each operation. Shorter cycles add up across thousands of parts, lowering lead times and boosting capacity without extra floor space.

Case study snapshot: measurable gains in a UK manufacturing plant

A mid-sized UK component manufacturer replaced manual assembly with a two-arm cobot cell plus machine vision inspection. The deployment used Universal Robots for collaborative arms and Cognex vision for quality checks.

Measured gains included a 30–40% throughput improvement, a 25% fall in defects and a marked uptime increase from fewer stoppages. Cycle time reduction and better yield produced a payback within 18–24 months, showing clear robotics productivity benefits in a real-world setting.

Baseline measurement before deployment and continuous post-installation monitoring were essential. Tracking pre- and post-automation cycle times, defect rates and labour costs made the improvements obvious and repeatable for plant managers.

Types of industrial robots and their efficiency roles

Manufacturers choose different robot families to match production goals. Each type brings distinct strengths for throughput, repeatability and flexibility. Understanding articulated robots, SCARA robots, delta robots and collaborative robots helps teams assign clear robotic cell roles on the shop floor.

Articulated robots offer multi-axis reach and dexterity from vendors such as ABB, KUKA and FANUC. Their 4–7 axis arms suit complex assembly, welding and material handling. High repeatability and payload capacity let plants reduce changeover time and handle varied product runs with precision.

Key selection points include repeatability (typically ±0.02–0.1 mm), reach, payload and IP rating for harsh environments. Tooling and force control matter when delicate assembly is required. These factors define how articulated robots deliver reliable, flexible production.

SCARA and delta robots excel where speed and repeatability are critical. SCARA robots favour horizontal tasks like PCB assembly and inserting operations. Delta robots use parallel-link kinematics for ultra-high-speed pick-and-place in packaging and food lines.

Both types drive parts-per-minute rates and reduce manual handling. Brands such as Epson and Omron supply SCARA lines, while FANUC and specialised makers provide delta-style solutions for rapid cycles. Using SCARA robots or delta robots helps boost output and lower variability in high-volume runs.

Collaborative robots change the way humans and machines work together. Universal Robots, Franka Emika and Fanuc’s CR series make lightweight, inherently safe units suited to close human interaction. Cobots UK adopters value fast commissioning, smaller footprints and lower integration cost.

Collaborative robots perform repetitive, precise subtasks while operators handle variation and decision-making. They suit small-batch and mixed-model production where rapid redeployment is essential. Limitations include lower payload and speed compared with heavy-duty articulated robots, so careful risk assessment remains necessary.

- Articulated robots: flexible assembly, high payloads and precision.

- SCARA robots: rigid, repeatable horizontal tasks and medium-speed assembly.

- Delta robots: ultra-fast pick-and-place for packaging and food sectors.

- Collaborative robots: safe human–robot teaming for SMEs and mixed production.

Automation technologies that amplify robotic impact

Robots deliver more value when paired with smart automation tools. Integrating vision, learning algorithms and connected analytics turns a simple arm into a responsive production partner. This section outlines practical technologies that raise throughput, cut defects and make factories more resilient.

Machine vision and sensors

High-resolution 2D and 3D cameras from suppliers such as Cognex, Keyence and Teledyne DALSA spot misalignments, surface flaws and measurement drift on the line. Vision-guided robots reduce human variability and lower escape rates by catching defects earlier.

Pairing vision with force and torque sensors enables adaptive correction during pick-and-place or finishing tasks. This blend of perception and feedback improves quality while shortening cycle time for repetitive operations.

AI and machine learning for adaptive control

AI in robotics applies motion planning and anomaly detection to refine performance over time. Machine learning models recommend parameter changes and help predict wear on critical parts.

Teams use platforms such as Siemens MindSphere or Rockwell Automation’s FactoryTalk and bespoke edge models to deploy predictive maintenance routines. The result is smoother operation, lower scrap and ongoing efficiency gains.

IoT connectivity and data analytics

Industrial IoT connects robots, sensors and PLCs so manufacturing analytics UK teams can monitor OEE, downtime and energy use in real time. Streamed data feeds MES and SCADA systems for instant alerts and dashboard visualisations.

Standards like OPC UA and MQTT, together with secure edge gateways, simplify integration and support compliance with UK data-handling expectations. Rapid insight into line balance and fault patterns fuels continuous improvement programmes.

When machine vision quality control, AI in robotics, predictive maintenance and industrial IoT converge, manufacturers unlock measurable gains. Clear data, adaptive control and secure connectivity make modern lines more efficient and easier to manage.

Economic benefits and return on investment for businesses

Investing in robotics can reshape cost structures and unlock measurable value. Managers in UK factories often see improved margins when they track both direct savings and wider operational gains.

Cost savings arise quickly from reduced labour overhead and lower scrap rates. Robots cut repetitive hours and overtime, which lowers the labour cost per part on high-volume lines. Better consistency and machine vision reduce scrap and rework, trimming material waste and warranty claims.

There are indirect reductions in expenses too. Fewer workplace injuries lead to lower absenteeism and insurance costs. Energy-efficient cell design and predictable uptime further increase cost savings automation delivers.

Speed of payback and long-term productivity gains

Typical projects reach an automation payback period between 12 and 36 months. Variations depend on task complexity, local labour rates, capital allowances and throughput uplift. Automotive welding cells often see faster returns because of volume and repeatability.

Robots enable consistent multi-shift production, so productivity gains UK firms enjoy compound over time. Cobots offer rapid redeployment for SMEs, shortening the payback through lower initial capital and flexible use.

How to evaluate ROI: metrics and calculation examples

Use a mix of metrics when assessing returns: TCO robotics, IRR, NPV and simple payback period. Include changes in OEE, reductions in scrap percentage and savings from lower labour hours.

- Start with a baseline: current labour cost per shift, parts per hour and scrap rate.

- Estimate post-automation: expected throughput, reduced scrap and lower labour hours.

- Factor in maintenance, service contracts and conservative uptime assumptions.

Include UK financing options and incentives when modelling results. Leasing or vendor finance can spread capital costs, while tax allowances and grant schemes may improve the effective robotics ROI. A cautious, numbers-based approach gives a clear view of real-world returns.

Implementation considerations for UK manufacturers

Choosing and deploying robots calls for careful planning that matches technical needs with business goals. Start with a clear view of the task, scale and future changes to ensure the project delivers steady gains.

Selecting the right robot for the application and scale

Assess payload, reach, cycle time and repeatability against the production environment. Food or medical sectors demand washdown designs and compliance that affect choice.

Look for modularity and quick-change end-effectors to support product variations. That flexibility lowers changeover time and protects investment as volumes shift.

Evaluate vendors on local support, spare-part availability and software ecosystems. ABB, FANUC, KUKA, Universal Robots and Yaskawa maintain UK presences that reduce downtime risks during rollout.

Integrating robots into existing production lines with minimal disruption

Use pilot cells to validate outputs before a full rollout. Digital twins from Siemens or Dassault Systèmes let teams test integration strategies without stopping production.

Confirm compatibility with PLCs, conveyors and MES by adopting standards such as OPC UA. This cuts custom engineering and speeds commissioning.

Plan staged commissioning during off-peak hours and secure clear service-level agreements with suppliers for rapid fault response. These steps keep disruption to a minimum.

Regulatory, safety and workforce training aspects in the United Kingdom

Follow BS EN ISO 10218 and ISO/TS 15066 alongside guidance from the Health and Safety Executive. A thorough risk assessment determines guarding, light curtains, area scanners or speed and separation measures.

Invest in workforce training to build durable capability. Courses in robot programming, routine maintenance and quality assurance create higher-skilled roles and support redeployment.

Work with local colleges and apprenticeship schemes to grow a talent pipeline. Emphasise supervision, maintenance and process engineering when communicating change to staff.

- robot selection UK should focus on fit, service and long-term flexibility.

- integration strategies must reduce downtime through simulation, standards and staged commissioning.

- manufacturing safety regulations UK require documented risk assessments and compliant safeguards.

- workforce training robotics strengthens adoption and shifts teams into higher-value roles.

Product review perspective: choosing robotic solutions that boost efficiency

A focused robotic product review begins by matching the robot type to the task. For heavy welding and high-payload assembly, consider ABB IRB or FANUC M-20 articulated cells; for high-speed pick-and-place look to delta offerings from FANUC and specialist packaging vendors. For precision small-part work, Omron and Epson SCARA models excel, while collaborative options from Universal Robots, Fanuc CR and Doosan Robotics suit small-batch, mixed-model lines.

Compare performance specs closely. Check repeatability, payload, cycle time, footprint, power draw and IP rating. Assess software and ecosystem: ease of programming, simulation tools, vision compatibility with Cognex or Keyence, and third-party integrations matter for rapid deployment. A clear industrial robot buying guide UK will recommend vendors with robust local service, spare-part logistics and training to protect uptime.

Price is more than upfront cost. Factor installation, systems integration, maintenance contracts and expected payback. Start with a pilot that targets the biggest bottleneck, record baseline KPIs and use conservative ROI assumptions. Use a modular cell with reputable vendors and add vision or IoT where quality monitoring is critical.

When choosing cobots, weigh collaborative safety features, ease of redeployment and cycle speed against throughput needs. This best robots for manufacturing approach — informed by a structured checklist and real-world pilots — turns investment into durable gains. A disciplined industrial robot buying guide UK helps transform repetitive chores into higher-value work, lifting quality, speed and competitiveness for British manufacturers.