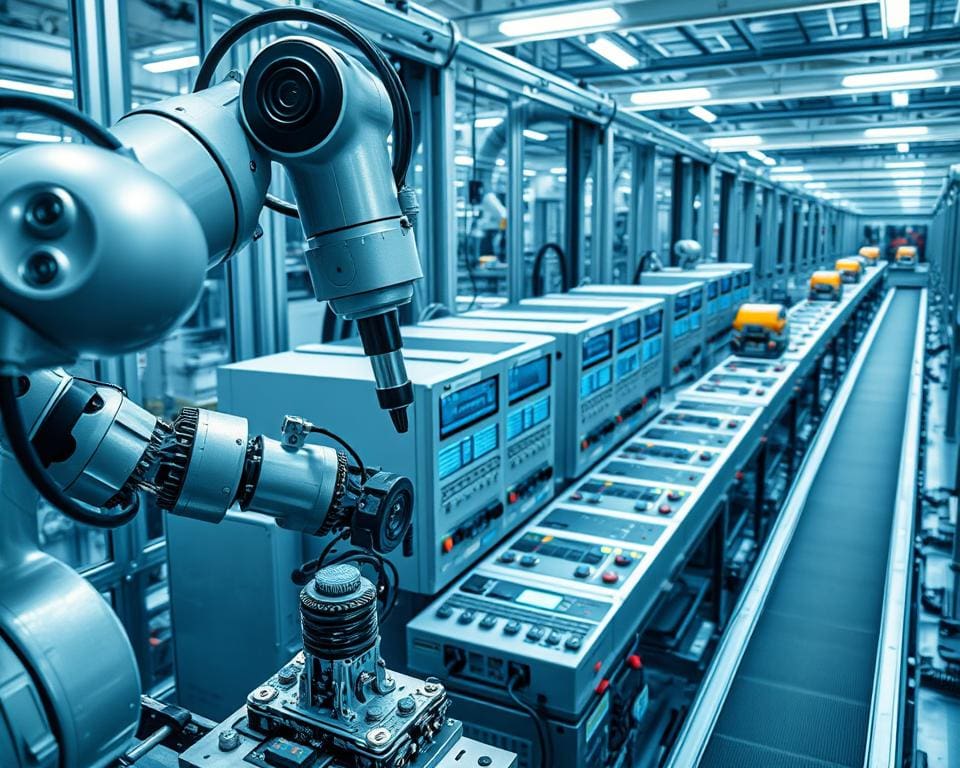

Industrial automation describes the use of hardware and software to carry out manufacturing and process tasks with minimal human intervention. In UK factories and process plants, automation hardware UK spans sensors, controllers, actuators and operator interfaces that together manage production, assembly, inspection and logistics.

The move to automated systems is accelerating across automotive, food and beverage, pharmaceuticals, chemicals and logistics. Government incentives and Industry 4.0 initiatives are encouraging investment in factory automation components to raise productivity, quality, safety and resilience.

This article adopts a product‑review approach to devices used in industrial automation. We compare device classes by function, list typical vendors such as Siemens, Rockwell Automation, ABB, Schneider Electric, Beckhoff and Honeywell, and highlight the specifications and safety certifications buyers should check.

Readers — procurement managers, plant engineers and automation integrators — will gain a clear framework to assess industrial control equipment. The aim is to help you prioritise investments, judge total cost of ownership and select devices that integrate reliably within your estate.

What devices are used in industrial automation?

Modern factories rely on a suite of devices that sense, decide and act. Each element plays a clear role in control, monitoring and optimisation. Together they form a responsive system that boosts uptime and quality.

Sensors and their role in data acquisition

Sensors convert physical phenomena such as temperature, pressure, flow, level and vibration into electrical signals. These data acquisition sensors feed control loops, SCADA systems and analytics platforms for condition‑based monitoring.

Common types include inductive and capacitive proximity sensors from Pepperl+Fuchs and SICK, Omron photoelectric sensors, WIKA and Fluke thermocouples and RTDs, Endress+Hauser and VEGA level sensors, Siemens flow meters, SKF vibration sensors and Honeywell gas detectors.

Key specs to check are measurement range, accuracy, response time, IP and ATEX ratings, signal types such as analogue 4–20 mA or IO‑Link, and calibration needs. Smart sensors with onboard diagnostics simplify IIoT integration and improve predictive maintenance.

Actuators and motion control devices

Actuators turn commands into movement. Electric servomotors, steppers, variable frequency drives, pneumatic cylinders and hydraulic actuators perform tasks from precise positioning to heavy lifting.

Brands such as ABB, Siemens, Yaskawa and Fanuc supply motors and drives. Festo and Parker Hannifin provide pneumatics and hydraulics. Mitsubishi Electric and Omron offer motion controllers that synchronise complex sequences.

Selection depends on torque, speed, encoder resolution, control mode and duty cycle. Safety functions like safe torque off and compliance with IEC 61800 matter. Most systems need tight feedback loops and compatibility with encoders for effective actuators motion control.

Programmable logic controllers (PLCs) for process control

PLCs are rugged industrial computers that run deterministic logic, interlocks and basic PID loops. They anchor machine control and link shop‑floor devices to higher‑level systems.

Leading PLCs for automation come from Siemens SIMATIC, Rockwell Automation Allen‑Bradley, Schneider Electric Modicon, Mitsubishi Electric and Beckhoff. Evaluate I/O capacity, scan time, modularity, redundancy and safety PLC functions.

Support for IEC 61131‑3 languages, fieldbus and Ethernet protocols, and options for motion modules determine how well a PLC integrates with drives, sensors and HMIs.

Human‑machine interfaces (HMIs) for operator interaction

HMIs provide visualisation, alarms and parameter entry that help operators and engineers manage machines. Clear displays shorten training time and speed fault diagnosis.

Panel HMIs such as Siemens WinCC and Schneider Magelis, industrial PCs from Beckhoff and Advantech, and browser‑based thin clients form common options. Consider screen size, ruggedness, multi‑language support, cybersecurity and historian linkage.

Good HMIs operator interface design uses trend plots, recipe handling and intuitive controls. That reduces operator error and supports faster recovery when issues arise.

Core control hardware driving industrial processes

Control hardware forms the backbone of modern factories and plants. Choosing the right mix of systems shapes reliability, safety and operational agility. Below we compare key families of controllers and outline when each fits best.

Distributed control systems (DCS) versus PLCs

Distributed control systems shine in continuous processing plants. Suppliers such as Honeywell, Emerson and Yokogawa supply solutions that tie control, historians and operator stations into a unified whole. These systems focus on loop management, redundancy and steady process performance.

Programmable logic controllers specialise in fast, discrete machine tasks. Rockwell Automation and Siemens PLCs excel on assembly lines, robotics and conveyor systems where modularity and rapid I/O response matter. Integrating PLCs with SCADA gives supervisory oversight for complex lines.

Many installations adopt a hybrid approach. A plant will run a DCS for bulk process control and PLCs at machine cells, joined via OPC UA, Modbus TCP or industrial Ethernet gateways. This mix preserves the strengths of both families while keeping integration flexible.

Industrial PCs and embedded controllers

Industrial PC controller platforms from Beckhoff, Siemens IPC and Advantech supply high compute density for demanding tasks. Panel PCs, rack servers and fanless embedded boxes host HMI, vision and edge analytics close to the process.

When selecting an industrial PC controller, assess CPU class, real‑time OS support, I/O expansion and MIL‑STD/EN environmental ratings. Reliable SSDs and serviceable components matter where uptime is non‑negotiable. Use cases include machine vision inspection with cameras from Basler or Cognex and advanced motion control for precision equipment.

Safety controllers and functional safety devices

Safety controllers protect people and assets through safety PLCs, safe I/O, light curtains, emergency stop systems and safety relays. Brands such as Pilz, Rockwell Automation (GuardLogix), Siemens (S7‑Safety), ABB and SICK lead in certified safety products.

Functional safety devices must meet standards like IEC 61508, IEC 62061 and ISO 13849. Seek systems with clear SIL or PL ratings and TÜV or DEKRA certification. Implement fail‑safe logic, scheduled proof testing and documented lifecycle management to keep safety measures effective.

- Choose DCS for chemical, oil & gas and power generation where process stability is critical.

- Pick PLCs for modular manufacturing, robotics and high‑speed machine control.

- Use industrial PCs where vision, edge analytics or complex HMI are required.

- Integrate safety controllers and functional safety devices at all hazard points and document testing regimes.

Communication technologies and industrial networking

The way machines talk shapes modern factories. Industrial networking brings together sensors, drives and control systems so plants run smarter and with greater agility.

Fieldbus protocols still play a key role on many shop floors. PROFIBUS remains common in legacy Siemens environments, while Modbus TCP/RTU offers simple, broad compatibility for older I/O and SCADA. CANopen is widely used where motion control and mobile platforms demand robust, compact links.

Many suppliers, including Beckhoff, Schneider Electric and ABB, support multiple fieldbus protocols on their I/O modules and drives. Migration often uses protocol gateways or dual‑stack devices so factories can move at their own pace.

Fieldbuses deliver deterministic, real‑time cycles that suit basic control tasks. They are cost effective for many use cases. Their limits appear when higher bandwidth, convergence and IIoT traffic become priorities.

Industrial Ethernet has become the backbone for converged operations. Variants such as PROFINET, EtherNet/IP and EtherCAT provide higher throughput, standard cabling and easier IT/OT integration.

Time‑Sensitive Networking, or TSN, extends Ethernet with time synchronisation and deterministic forwarding. TSN enables a single network to carry control, safety and real‑time data with low jitter and predictable latency.

Vendors like Siemens, Rockwell Automation, Beckhoff and Cisco supply TSN‑capable switches and devices. Deployments benefit from careful planning: VLANs, QoS policies and redundant topologies such as PRP or HSR improve resilience and performance.

Wireless links free machines from fixed cabling. Industrial Wi‑Fi (802.11ax) handles high throughput needs, while Bluetooth LE suits battery‑powered sensors and short‑range telemetry.

Private 5G for industry is gaining traction for large sites that need ultra‑reliable, low‑latency wireless. Nokia, Ericsson and Huawei offer private network solutions that target mobile robots, AGVs and high‑density sensor layers.

Wireless comes with challenges: interference, spectrum planning and security. Best practice calls for detailed site surveys, hardened access points, strong authentication and redundant paths to meet production demands.

Smart devices and IIoT components transforming factories

Factories today blend traditional machinery with modern IIoT devices to unlock faster decisions and clearer insight. Small, smart modules capture data at the source and feed local systems or cloud platforms for deeper analysis.

Edge gateways and edge computing devices

Edge gateways from vendors such as Cisco, HPE Edgeline and Advantech gather OT signals, translate protocols and run containerised apps close to production lines. Support for OPC UA, MQTT and AMQP is a common requirement when teams evaluate edge computing industrial solutions.

Secure boot, TPM and remote update orchestration are key features to check. Processing at the edge reduces bandwidth costs, speeds decision loops and keeps operations resilient during cloud outages.

Condition monitoring sensors and predictive maintenance tools

Condition monitoring relies on vibration sensors, ultrasonic detectors and thermal cameras from brands like SKF, Fluke, UE Systems and FLIR. Smart bearing sensors and integrated platforms from Siemens and ABB turn raw signals into timely alerts.

Analytics range from FFT vibration analysis to machine learning that estimates remaining useful life. Integration with IBM Maximo or SAP EAM helps convert alerts into scheduled work orders and measurable ROI.

Cloud platforms and analytics engines

Cloud platforms such as AWS IoT, Microsoft Azure IoT and Siemens MindSphere provide ingestion, time‑series storage and tools for digital twins. Organisations choose cloud analytics for industry when they need scale, model training and ERP or MES integration.

- Consider data residency, GDPR and UK cybersecurity rules when designing hybrid edge + cloud architectures.

- Assess APIs, prebuilt connectors and vendor ecosystems for faster deployment and domain expertise.

End‑user devices and peripheral equipment in automation systems

Automation peripherals such as barcode scanners, industrial cameras and labelling systems turn control-room decisions into on‑the‑ground action. Devices from Zebra Technologies and Honeywell provide fast barcoding and RFID reading for traceability, while Cognex and Basler machine‑vision cameras inspect parts for defects at line speed. These industrial peripherals bridge identification, quality inspection and operator mobility, often linking to PLCs and HMIs via USB, serial, Ethernet or wireless links.

Selection must weigh environment and durability as much as features. Choose IP‑rated barcode scanners and printers if the site uses conveyors or wash‑down routines, and pick torque tools and calibrated test instruments from Fluke or Kistler that tolerate vibration and wide temperature ranges. Labelling systems and industrial barcode printers should offer clear consumable availability and straightforward mounting and cabling for rapid replacement.

Integration and usability drive value. Prefer peripherals that support OPC UA, MQTT or vendor SDKs so middleware or direct HMI connections are straightforward. Ergonomic handheld terminals, multi‑language interfaces and simple software lower training needs and speed deployment. Consider after‑sales support in the UK: local service centres, authorised partners, spare parts and warranty terms reduce downtime and lifecycle cost.

Futureproofing reduces total cost of ownership. Select devices that accept firmware updates, use standard interfaces and are modular enough to add IIoT edge gateways later. Factor in maintenance contracts, software licences and cybersecurity patching when evaluating price, and favour suppliers with established UK support to keep production moving and innovation within reach.