Batch production is a pivotal concept in GCSE business studies, referring to a manufacturing method where products are produced in groups or batches, rather than in a continuous flow. This approach is integral for students as it illustrates essential principles of production management and prepares them for various industrial applications. By exploring the batch production definition, learners gain insight into its significance in sectors like food and textiles, making this topic a foundation for understanding contemporary manufacturing processes.

Understanding Batch Production Definition

Batch production is a key manufacturing method that plays a vital role in various industries. This technique involves the production of goods in specified groups or batches, allowing for flexibility and adaptability in product design. Understanding the batch production definition is essential, especially for students who find this concept important in gcse business studies.

What Is Batch Production?

Batch production refers to the process where items are produced in distinct sets, as opposed to continuous production or one-off manufacturing. Each batch goes through a series of stages, where modifications can be made between batches. This method appeals to manufacturers who require flexibility and variations in their offerings, catering to markets that demand seasonal or customised products.

Historical Context of Batch Production

The roots of batch production can be traced back to the Industrial Revolution. During this transformative period, craftspeople began to adopt more structured and systematic methods of production. This marked a significant transition from handmade items to goods produced in batches, greatly enhancing efficiency and improving product availability.

What Is Batch Production Gcse Business

Batch production represents a vital concept within GCSE business studies. Understanding its significance equips students with the ability to evaluate various manufacturing strategies effectively.

Importance in GCSE Business Studies

The importance in GCSE business studies is paramount as batch production highlights practical applications in real-world scenarios. Students learn about operational efficiency, cost management, and market demand—elements crucial for navigating the complexities of modern business. This foundational knowledge prepares them for future challenges within the enterprise landscape.

Key Characteristics of Batch Production

Among the key characteristics of batch production are its capacity to create different products in specified quantities and the dependence on specialised equipment designed for such processes. This method promotes a streamlined approach to quality control, ensuring consistency across batches. Additionally, batch production caters to consumer preferences for personalised products while maintaining a prudent balance between manufacturing costs and market expectations. Such aspects become integral to effective gcse business revision, enabling students to grasp the intricacies of production strategies.

Advantages of Batch Production

Batch production offers numerous benefits that make it a attractive choice for manufacturers aiming to enhance their operations. Its distinctive features cater to a wide range of industry needs, allowing businesses to thrive in competitive markets.

Flexibility in Manufacturing

The flexibility in manufacturing is one of the key advantages of batch production. Companies can easily switch between different product lines, minimising downtime during transitions. This adaptability enables manufacturers to respond quickly to changing market demands, ensuring they stay relevant and competitive.

Quality Control Benefits

Focused inspection during the production process yields significant quality control benefits. Each batch can be thoroughly reviewed, allowing for necessary adjustments to be made in real-time. This concentrated oversight leads to higher-quality products, which enhances customer satisfaction and brand loyalty.

Resource Efficiency and Cost-effectiveness

Resource efficiency is another critical aspect of batch production, as it reduces waste during the manufacturing process. By optimising resources, companies can achieve a more sustainable approach while maintaining their output levels. This balance significantly contributes to the cost-effectiveness of batch production, allowing businesses to make strategic savings without sacrificing quality.

Disadvantages of Batch Production

While batch production can offer various benefits, it is essential to acknowledge its disadvantages of batch production that may hinder a business’s overall performance. These challenges often influence decision-making processes in manufacturing.

Potential for Production Delays

A significant concern within batch production is the potential for production delays. When switching from one batch to another, considerable time and resources may be required for reconfiguration or adjustments. Such interruptions can impede a company’s ability to fulfil customer demand efficiently, resulting in a backlog of orders and potential dissatisfaction among clients.

Higher Setup Costs

The process of changing production patterns does not come without its financial implications, which brings us to the topic of higher setup costs. Each time a new batch is prepared, investment in recalibrating equipment or installing new machines may be necessary. These costs can erode the initial profitability, making it essential for companies to weigh the benefits against these financial burdens.

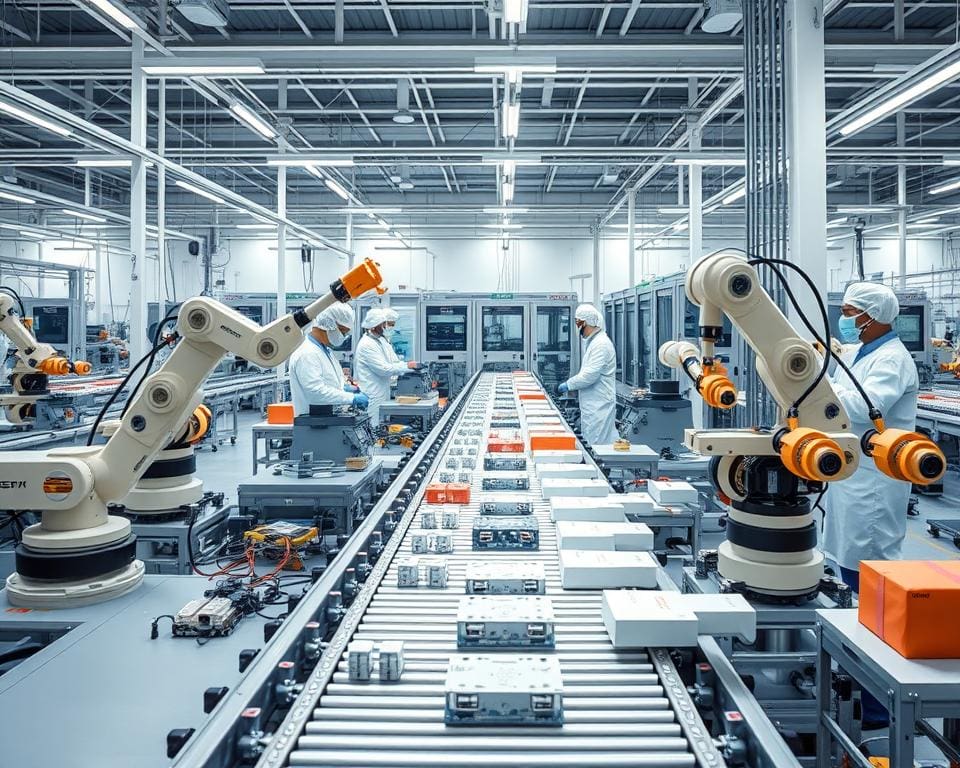

Batch Production Techniques and Examples

Batch production techniques play a crucial role in many industries, enhancing efficiency and product quality. One common method involves the use of assembly lines, where tasks are divided among skilled workers. This approach not only accelerates the manufacturing process but also allows for a more streamlined workflow. Such methods are essential for businesses aiming to maintain competitiveness in today’s fast-paced market.

Notable examples of batch production can be found in the baking industry, with products like artisan bread or seasonal pastries being produced in batches. This practice helps ensure consistency while enabling bakers to introduce new flavours depending on the time of year. Similarly, in the textile sector, brands such as Burberry often produce clothing lines in batches to swiftly respond to changing fashion trends while optimising the use of materials.

By examining these examples of batch production, students can grasp the practical implications of their GCSE studies. Real-world scenarios illustrate how these techniques not only improve manufacturing efficiency but also align with consumer demands. Understanding batch production techniques enriches the educational experience, bridging the gap between theoretical knowledge and practical application in various industries.